#4 Repairing holes

Support: Saemi Lee

#4 Repairing holes

Support: Saemi Lee

- Repair as you go

- Material-specific repair methods

- Repairing holes in knitted Merino wool products

- Repairing holes in woven fabric products

- Repairing holes in synthetic fiber fabrics

- Repairing holes in backpack fabrics

- Repairing holes in silicone-coated backpack fabric

- Case studies by product

- BACKPACKS

- Rainwear

- Active Insulation

- Bottoms

- Trail shirts

- MERINO WOOL

- Hats

Everyday at Yamatomichi, we handle repairs for many products, but the most common are repairs for holes.

Nevertheless, while we may refer to it simply as “patching holes,” the repair methods vary depending on the material, such as Merino wool, waterproof membranes, and backpack fabrics. In this episode of Yamatomichi repair diary, the theme is “holes.” We introduce repairs on all sorts of materials from past examples.

If your Yamatomichi product develops a hole, please don’t hesitate to contact our repair department. Our staff will do their utmost to fix it!

Repair as you go

For some reason, I have love old things. Especially, I have a soft spot for chunks of iron like industrial sewing machines. My journey into the world of craftsmanship began with being drawn to industrial tools.

Even when I first moved to Tokyo and was living in a flat without a bathtub and earning a modest salary, I dedicated my room to a large industrial vacuum ironing board and industrial sewing machine (whether I actually used them is another matter…).

Why am I so drawn to such old industrial tools? They’re certainly not versatile or convenient, but tools made simply for a specific purpose have a certain charm. And I inevitably find myself admiring the way people from past eras made a living using these simple tools and their physical abilities. It might just be a skewed nostalgia, though.

And one common factor among them is their weight.

There’s a reason for this; for example, industrial sewing machines, unlike household ones, are made of a solid chunk of iron, so they’re unusually heavy. However, this weight helps to dampen the vibrations when the machine rotates, contributing to stability during sewing. Moreover, they’re so robust that they’re not easily damaged.

Similarly, the irons used by tailors are as heavy as dumbbells. This is because when shaping wool used in suits to fit the body’s curves, heat and pressure from the iron become crucial.

Encountering Yamatomichi, which advocates for ultralight gear, was undoubtedly a shock for someone like me who loves ultraweights.

The heavy tools I’ve liked and used so far pursued one purpose to the fullest: they were “tools for tools.” However, the tools selected for ultralight hiking are viewed from an entirely different perspective, focusing not only on the performance of the tool but also on how freely the person using it can move.

After joining Yamatomichi, I found the world of ultralight, which lead me to the process of breaking free from the curse of the weight of my life problems, though I still love big, heavy chunks of iron.

While lightweight tools may not be as robust as heavy ones designed with durability in mind, they offer opportunities for users to innovate and adapt. While lifelong tools are admirable, there’s equal value in continuing to use and repair them even after they break. I’ve come to realize this through repairing customers gear, here at Yamatomichi.

Material-specific repair methods

Repairing holes varies depending on the characteristics of the material. For example, with Merino wool, we utilize its felting property to blend the fabric, while with synthetic fibers, we take advantage of their melting properties to heat-cut the fabric edges and create repair sheets.

Normally, what might be considered a drawback of the fabric (such as wool felting) can become an advantage in repairs. Considering methods for repairing holes can be a good opportunity to confront the characteristics of the fabric.”

Repairing holes in knitted Merino wool products

Raw wool felting repair

Relevant products (as of March 2025)

100% Light Merino Henley / 100% Merino Pullover / 100% Merino Half Zip Hoody / 100% Merino Zip Hoody / Merino Cap / 100% Light Merino Pocket T-shirt / 100% Light Merino Kangaroo / 100% Light Merino Sleeveless / 100% Light Merino French Sleeve / 100% Light Merino Long Sleeve

For holes in knitted Merino wool products like 100% Merino Half Zip Hoody and 100% Light Merino Pocket T-shirt, we repair using a method called felting with raw wool. This process is detailed in our journal entry, “Yamatomichi Repair Diary #1.”

Due to the nature of knitted fabrics, holes can form from weakened fibers due to insect damage or friction. Initially, these holes may be small, but they can quickly widen if left unattended. Since it’s easy to overlook, it’s a good idea to occasionally inspect the fabric under light to identify any holes.

We apply raw wool to the affected area and felt it to close the hole. Using wool of the same color, we can repair relatively small holes of around 5mm without them being too noticeable.

July 2023 Update:

For Yamatomichi 100% Merino Series products and 100% Light Merino Series products manufactured after 2021, the yarn structure has changed from twisted yarn to single yarn, requiring even more careful handling. If you’re unsure about the repair process, our repair department accepts hole repair requests. Please contact us via the Repair Page for inquiries.

Repairing holes in woven fabric products

Patche repair fabric, whipstitching.

Relevant products (as of March 2025):

Merino 5-Pocket Pants / Merino Coach Jacket / Merino Short Sleeve Shirt / Merino Shirt / Bamboo Short Sleeve Shirt / Bamboo Shirt

Next, let me introduce the method for repairing holes in woven fabric (textile) products such as the Merino Shirt, Merino 5-Pocket Pants, and Bamboo Shirt.

Fabrics made from natural fibers tend to have thicker yarns compared to synthetic fibers, making them more prone to fraying. Additionally, due to the pronounced surface texture, adhesive bonding with repair sheets is not feasible. Therefore, for hole repairs, we use a patching fabric as an underlay and mend it with a sewing machine.

We place a piece of fabric cut slightly larger than the hole on the underside and repeatedly stitch back and forth with a sewing machine to close the hole, employing a whipstitching technique. This results in a very sturdy repair. However, there are drawbacks such as the repaired area being noticeable from the front and the repaired portion becoming stiff.

Repairing holes in synthetic fiber fabrics

We repair using repair sheets made with patching fabric.

Relevant products (as of March 2025):

Light 5-Pocket Short Shorts / Light 5-Pocket Shorts / Light 5-Pocket Pants / DW 5-Pocket Shorts / DW 5-Pocket Pants / 5-Pocket Shorts / 5-Pocket Long Shorts / 5-Pocket Pants / Alpha Anorak / Light Alpha Vest/Jacket / Alpha Haramaki

Next, I’ll explain the method for repairing holes in products made with synthetic fibers, such as the 5-Pocket Pants, Alpha Anorak, and UL Rain Hoody.

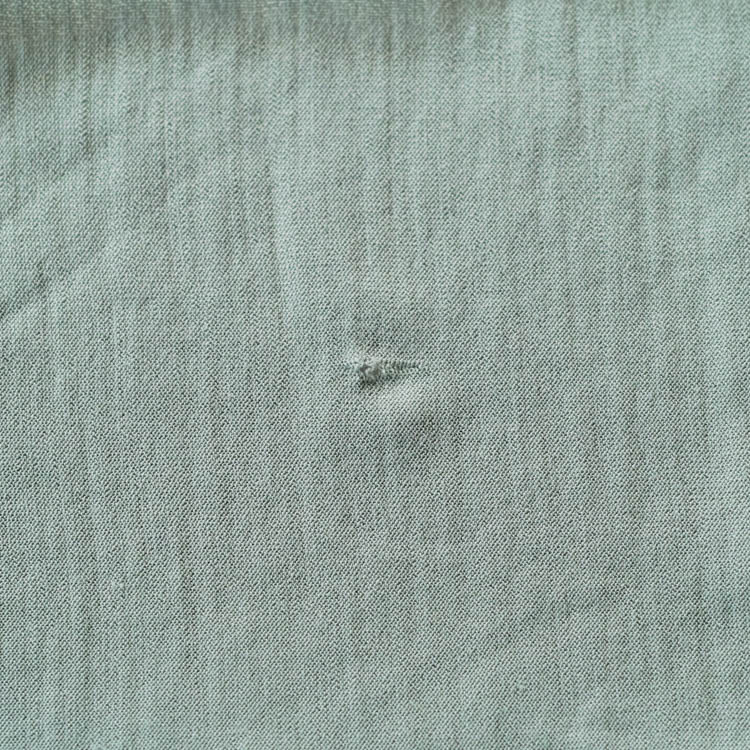

The synthetic fiber fabrics used by Yamatomichi are often very thin and lightweight. When they come into contact with sharp objects like rocks or branches, they can develop scratches that may lead to tears in the fabric.

While a whipstitching technique for repairs would be preferable for durability, the thinness of the fabric makes the repair stitches quite noticeable and may result in stiffened areas.

Therefore, for such thin fabrics, we use repair tape with double-sided adhesive sheets. By ironing the repair tape onto the area with the hole, the repair can be made relatively inconspicuously. For larger holes, the surrounding area is further reinforced with machine stitches.

While the strength may not be as high as with whipstitching, this method offers the advantage of being less noticeable, and if the tape begins to peel off, it can be easily repaired with more repair tape and an iron.

Repairing holes in backpack fabrics

Patch Repair

Relevant products (as of March 2025):

MINI / MINI2 / MINI Custom Edition / THREE / ONE / ONE Custom Edition

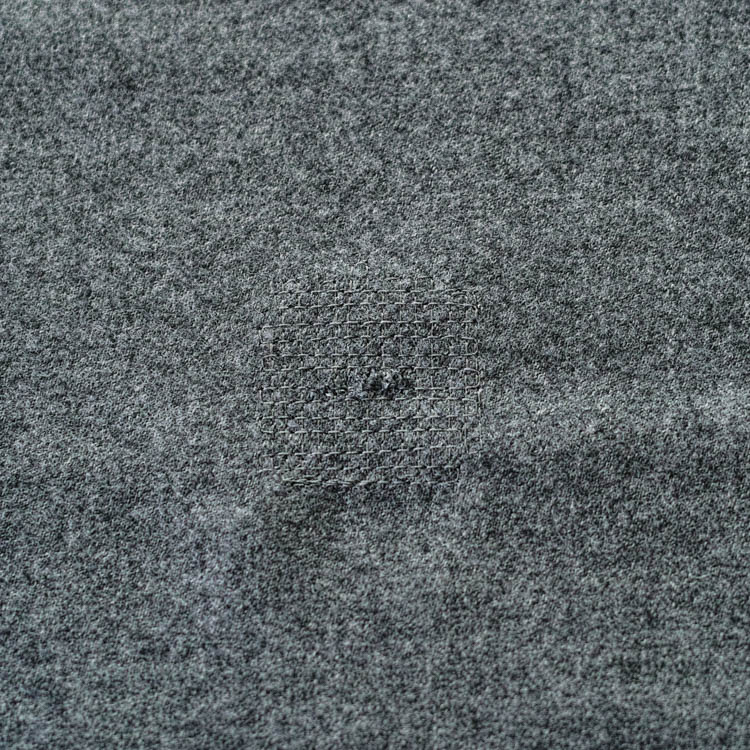

Fabrics like X-Pac, commonly used for the body and bottom of backpacks, are known for their high durability. However, prolonged friction or contact with sharp objects can still lead to holes. These fabrics tend to be stiff and often coated, making it challenging to perform complete repairs once a hole forms.

In cases of significant damage or deterioration, replacing individual parts is generally preferable for both durability and appearance. However, for backpacks with sentimental value, repairing using repair sheets while preserving the existing parts is also an option.

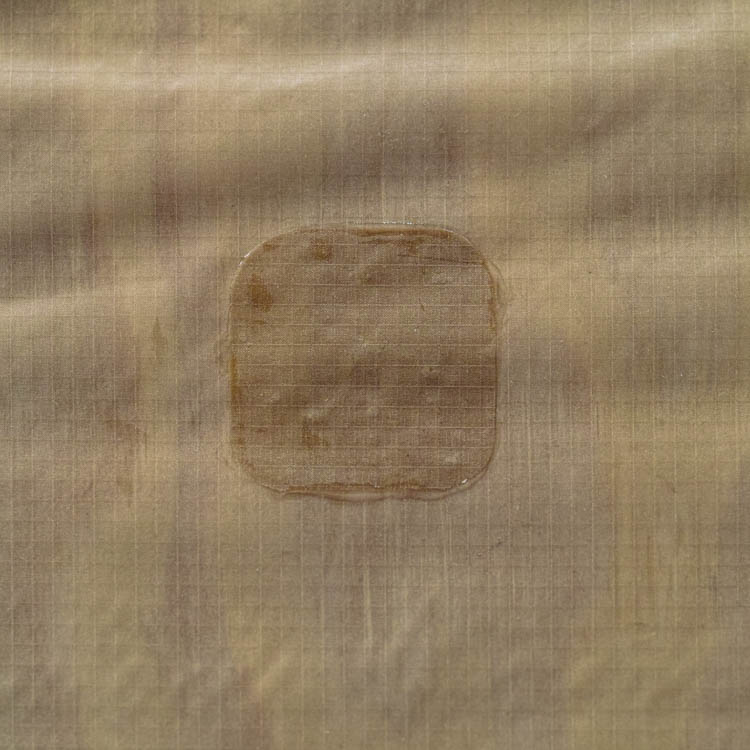

We use double-sided adhesive sheets, similar to those used for pants repairs, for iron-on repairs.

Repairing holes in silicone-coated backpack fabric

Patch repair

Relevant products: (as of March 2025)

MINI (models prior to 2020) / MINI2 (models prior to 2020) / THREE (models prior to 2020) / ONE / MINI Custom Edition

For silicone-coated nylon fabrics used in backpack bodies and similar areas, double-sided adhesive sheets cannot be used due to the silicone coating. Therefore, we repair by adhering a patching fabric with silicone-specific adhesive.

Considering water resistance, we prefer not to use machine stitching if possible. However, due to the comparatively weaker durability of other repair methods, it’s common to reinforce the adhesive with machine stitching after application.

Case studies by product

At Yamatomichi Repair Department, when we receive items for repair from our customers, we always inquire about the cause of the hole or damage.

There is always a reason behind the formation of a hole, and by understanding it, we can deepen our understanding of the product’s weaknesses and how it’s being used. The valuable feedback we receive is also incorporated into our product development process.

As repair specialists, we take joy in being able to repair items while considering the story behind each hole and comparing the received product with the user’s personality

BACKPACKS

ONE

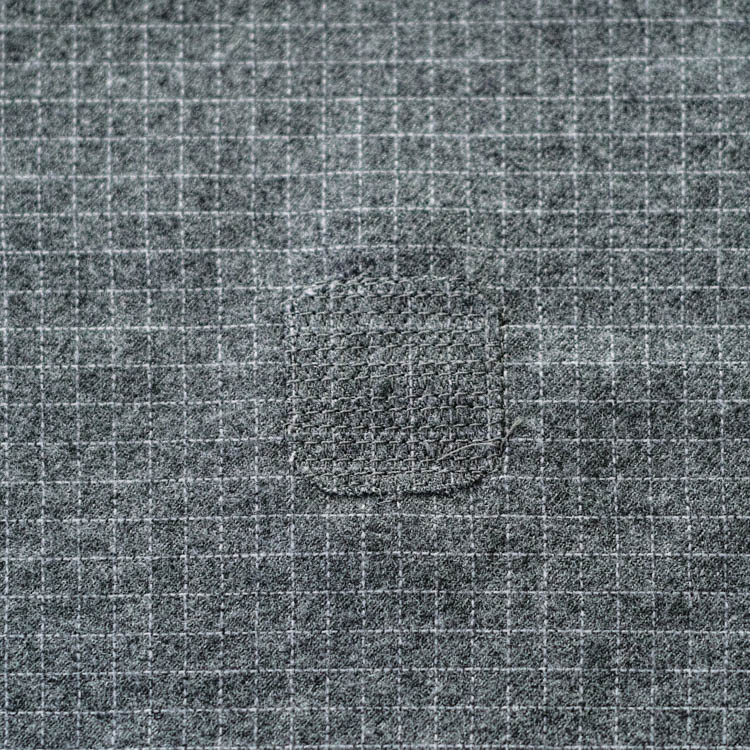

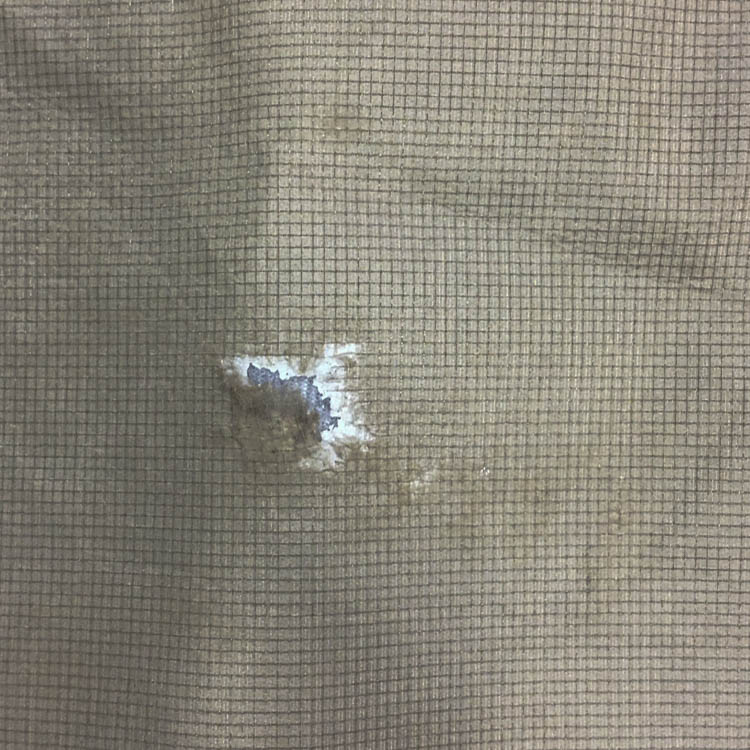

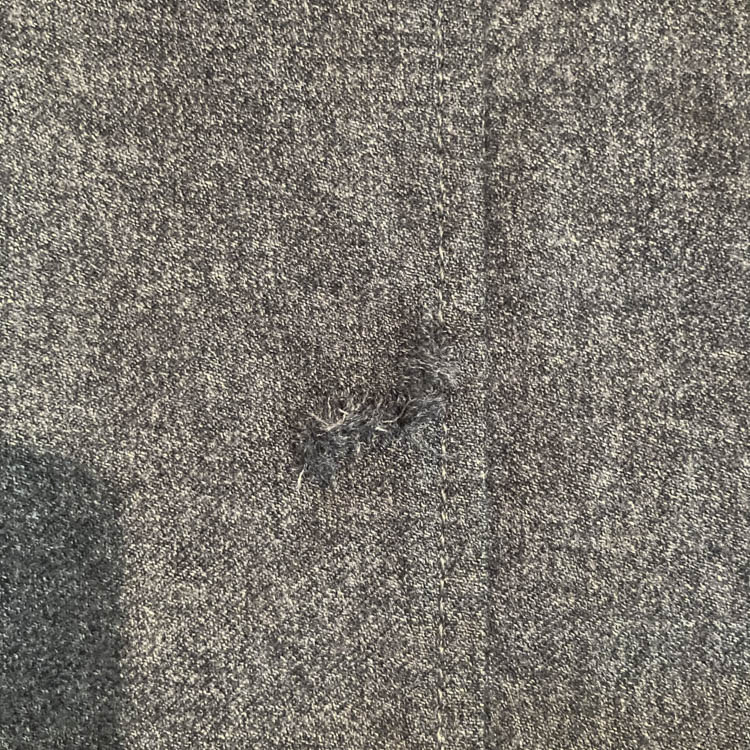

Condition: Small hole at the butt

Cause: Contact with a rock while putting items in the side pocket

Repair Method: Repair sheet and stitching reinforcement

Repair Cost: ¥500

BEFORE

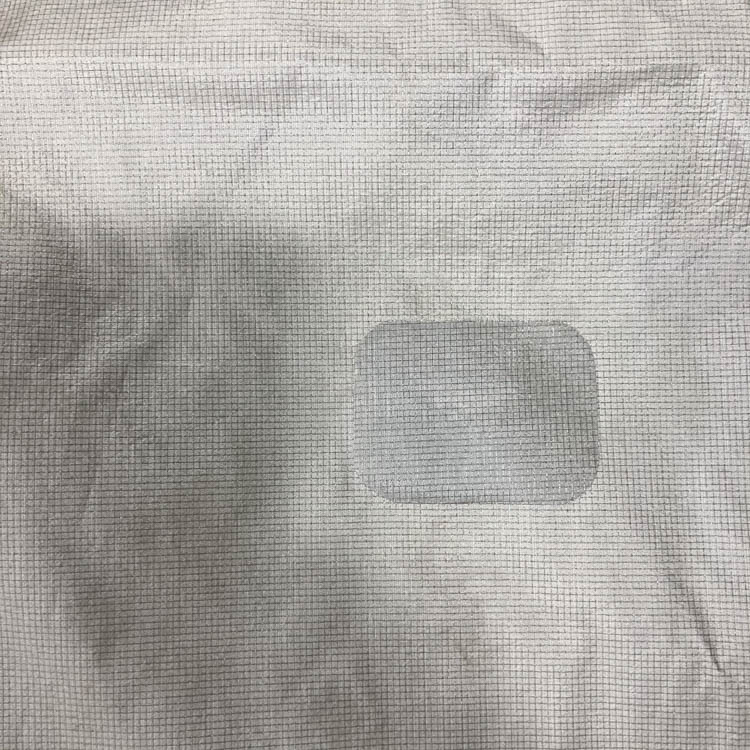

AFTER

ONE

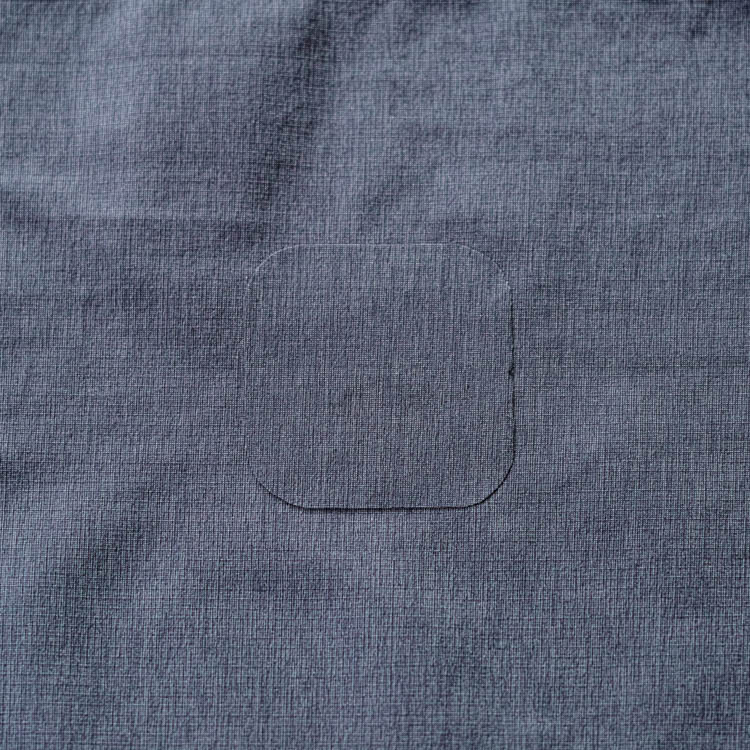

Condition: Medium-sized hole in the pocket section

Cause: Wear and tear during use on long trails

Repair Method: Repair with a repair sheet

Repair Cost: ¥500

BEFORE

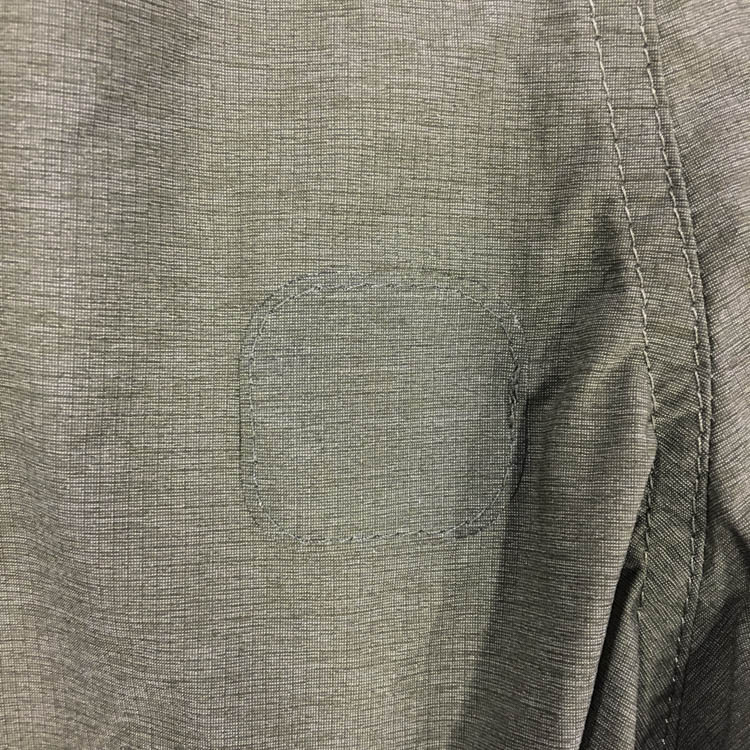

AFTER

THREE

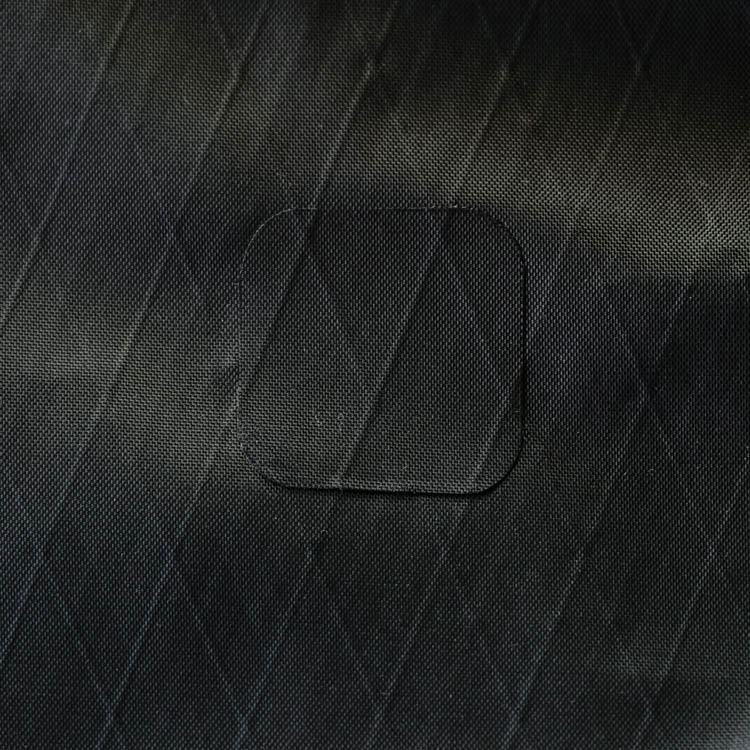

Condition: Small hole at the bottom corner

Cause: Repeated contact with rocks

Repair Method: Unstitching the sewing area and applying a patching fabric for repair

Repair Cost: ¥500

BEFORE

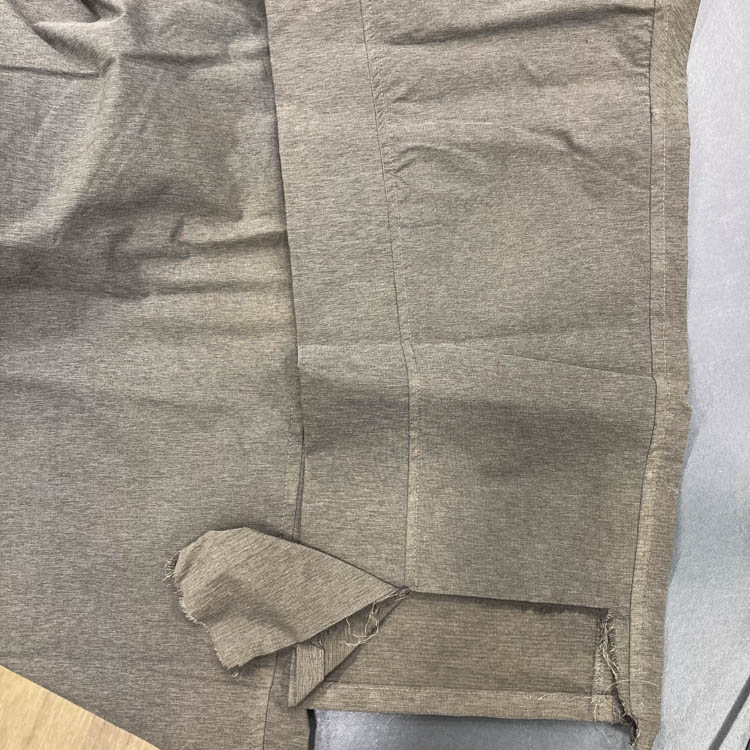

AFTER

MINI2

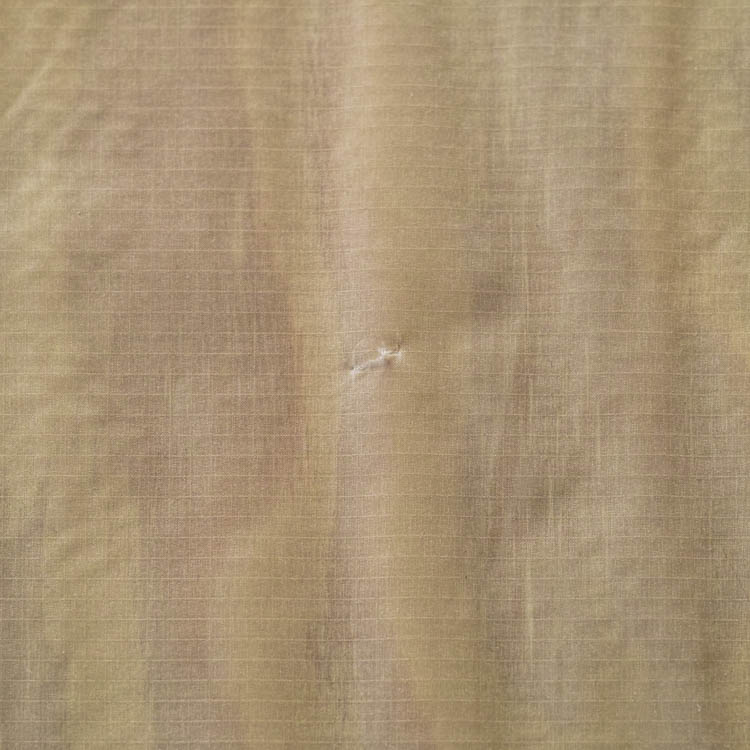

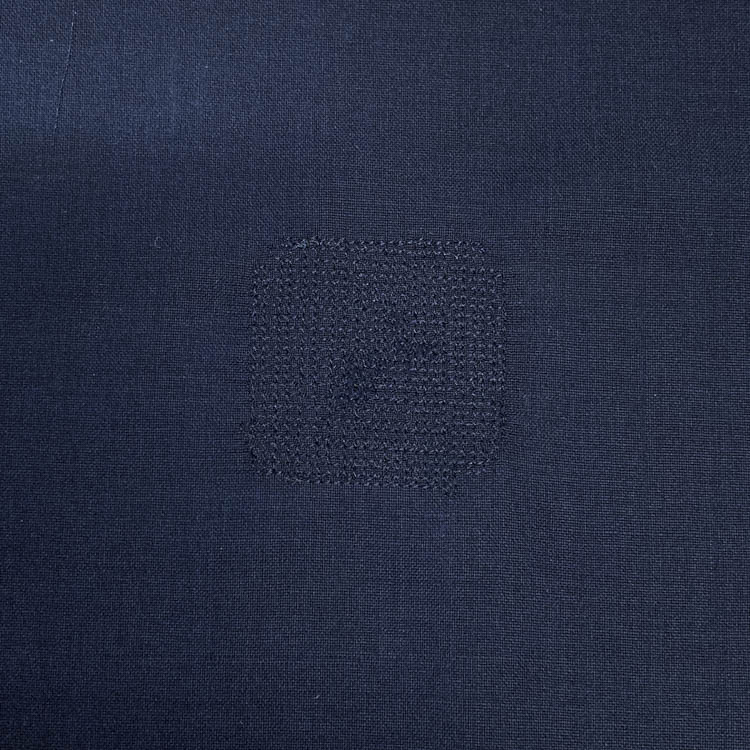

Condition: Small hole in the body section

Cause: Contact with sharp objects packed inside

Repair Method: Patching fabric and stitching reinforcement using adhesive

Repair Cost: ¥500

BEFORE

AFTER

MINI2

Condition: Medium-sized hole in the extension section

Cause: Contact with sharp objects packed inside

Repair Method: Patching fabric and stitching reinforcement using adhesive

Repair Cost: ¥500

BEFORE

AFTER

Rainwear

UL Rain Pants PU Shinsui

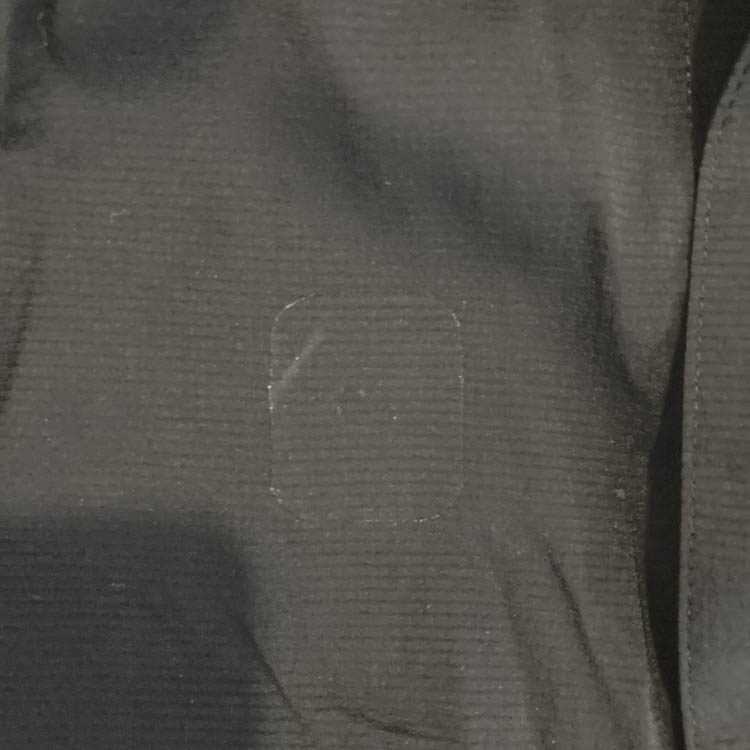

Condition: Small hole at the knee area

Cause: Contact with a wooden branch

Repair Method: Repair with a repair sheet

Repair Cost: ¥500

BEFORE

AFTER

UL Rain Pants PU Sosui

Condition: Medium-sized hole at the hem

Cause: Wear and tear during use

Repair Method: Double repair with repair sheets

Cost: ¥1,000

BEFORE

AFTER

Active Insulation

Alpha Anorak

Condition: Small hole at the cuff

Cause: Sparks from a campfire

Repair Method: Repair with a repair sheet

Cost: ¥500

BEFORE

AFTER

Light Alpha Vest/Jacket

Condition: Medium-sized hole at the cuff

Cause: Campfire

Repair Method: Repair with a repair sheet

Cost: ¥2000

BEFORE

AFTER

Alpha Anorak

Condition: Large hole at the cuff

Cause: Campfire

Repair Method: Cut damaged portion and patch repair

Cost: ¥2,000

BEFORE

AFTER

Bottoms

Light 5-Pocket Short Shorts

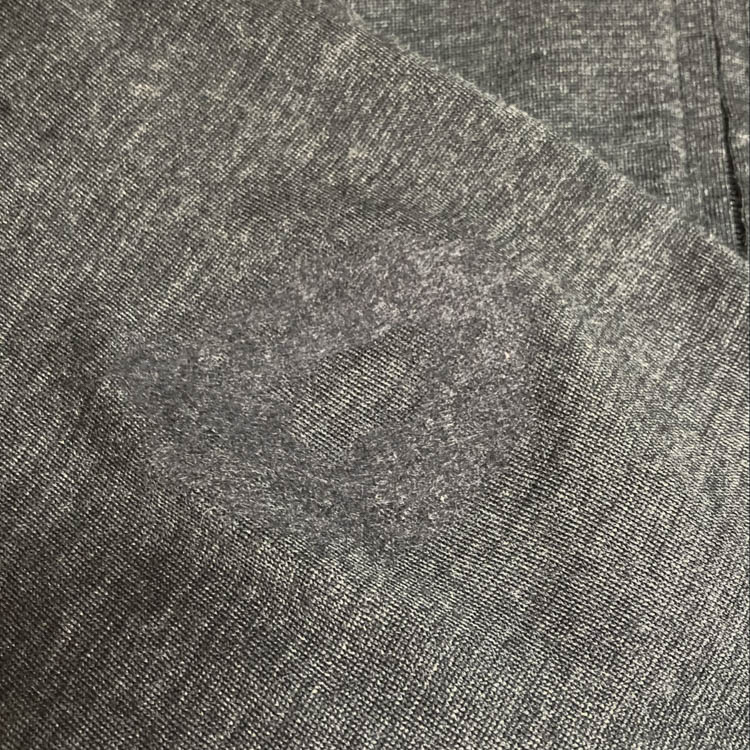

Condition: Small hole at the hip

Cause: Contact while descending rocky terrain

Repair Method: Repair with a repair sheet

Cost: ¥500

BEFORE

AFTER

Light 5-Pocket Pants

Condition: Medium-sized hole at the knee

Cause: Fall

Repair Method: Repair with a repair sheet and stitching reinforcement

Cost: ¥1,000

BEFORE

AFTER

Light 5-Pocket Pants

Condition: Large hole at the hem

Cause: Snagging

Repair Method: Unstitching the sewing area and repair with a repair sheet

Cost: ¥1,500

BEFORE

AFTER

5-Pocket Pants

Condition: Small hole at the hem

Cause: Campfire

Repair Method: Repair with a repair sheet

Cost: ¥500

BEFORE

AFTER

Winter Hike Pants

Condition: Medium-sized hole at the hem

Cause: Contact with crampons

Repair Method: Unstitching the seam and repair with a repair sheet and stitching reinforcement

Cost: ¥1,500

BEFORE

AFTER

5-Pocket Merino Pants

Condition: Medium-sized hole

Cause: Contact during daily activities

Repair Method: Patching fabric and stitching reinforcement

Cost: ¥1,000

BEFORE

AFTER

Trail shirts

UL Shirt

Condition: Small hole in the front body section

Cause: Campfire

Repair Method: Repair with a repair sheet

Cost: ¥500

BEFORE

AFTER

Merino Shirt

Condition: Medium-sized hole

Cause: Snagging

Repair Method: Patching fabric and stitching reinforcement

Cost: ¥1,000

BEFORE

AFTER

MERINO WOOL

100% Light Merino Henley

Condition: Small hole at the shoulder

Cause: Yarn breakage due to abrasion

Repair Method: Felting repair

Cost: ¥500

BEFORE

AFTER

100% Light Merino Pocket T-shirt

Condition: Medium-sized hole at the underarm

Cause: Yarn breakage due to abrasion

Repair Method: Felting repair

Cost: ¥1,000

BEFORE

AFTER

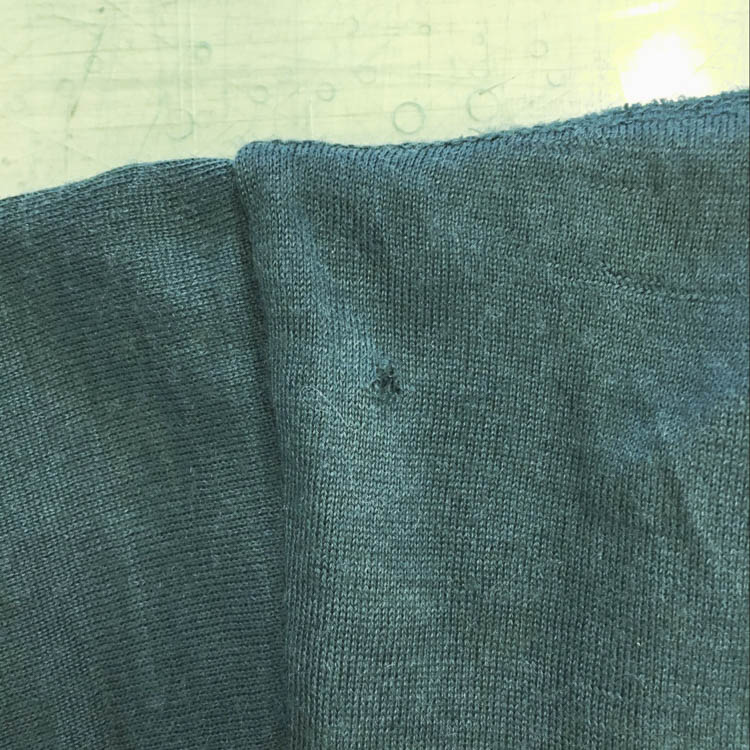

100% Merino Half Zip Hoody

Condition: Medium-sized hole at the pocket corner

Cause: Yarn breakage due to stress

Repair Method: Felting repair

Cost: ¥500

BEFORE

AFTER

100% Merino Half Zip Hoody

Condition: Large hole at the elbow

Cause: Contact with sharp object

Repair Method: Felting repair with patching fabric

Cost: ¥1,500

BEFORE

AFTER

Hats

Merino Knit Cap

Condition: Hole at the crown

Cause: Stitching unraveling

Repair Method: Stitching

Cost: ¥500

BEFORE

AFTER

Merino Cap

Condition: Small hole

Cause: Yarn breakage due to moth damage and abrasion

Repair Method: Felting repair

BEFORE

AFTER

Yamatomichi Product Repair Price List

*Prices are approximate.

*All prices include tax.

*Shipping fee is charged separately.

Felting Repair (for Merino Wool Knit Products)

- Small hole within 1cm: ¥500 per hole and up

- Large hole exceeding 1cm: ¥1,000 per hole and up

Sewing Patch Repair (for Natural Fiber Products)

- Small hole within 1cm: ¥1,000 per hole and up

- Large hole exceeding 1cm: ¥1,500 per hole and up

Repair Sheet Repair (for Backpacks and Synthetic Fiber Products)

- Small hole within 1cm: ¥500 per hole and up

- Large hole exceeding 1cm: ¥1,000 per hole and up

Repair Team